Trauma Implant OEM Manufacturing Solutions

Clinical Importance and the Role of Trauma Implants

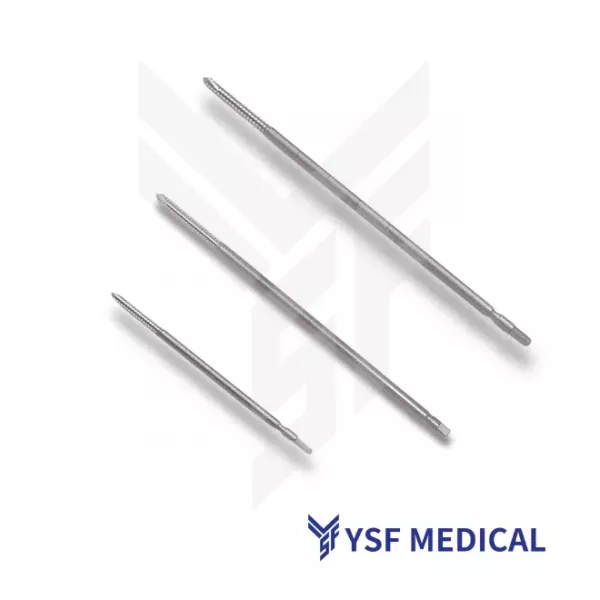

Bone trauma is one of the most common challenges in healthcare worldwide. From traffic accidents to everyday falls, complex fractures can occur, necessitating effective interventions to restore normal mobility. Physicians rely on various trauma implants, such as bone plates, intramedullary nails, and screws, to stabilize fractured bones and promote healing. These implants serve a purpose beyond simple fixation; they are essential for helping patients regain their quality of life. For example, in the treatment of long bone fractures, the design and reliability of the implant directly influence surgical success and recovery time. This highlights the need for trauma implant design and manufacturing to strike a balance between mechanical strength, durability, and biocompatibility, thereby effectively meeting clinical requirements.

The Value of OEMs: Partners Beyond Manufacturing

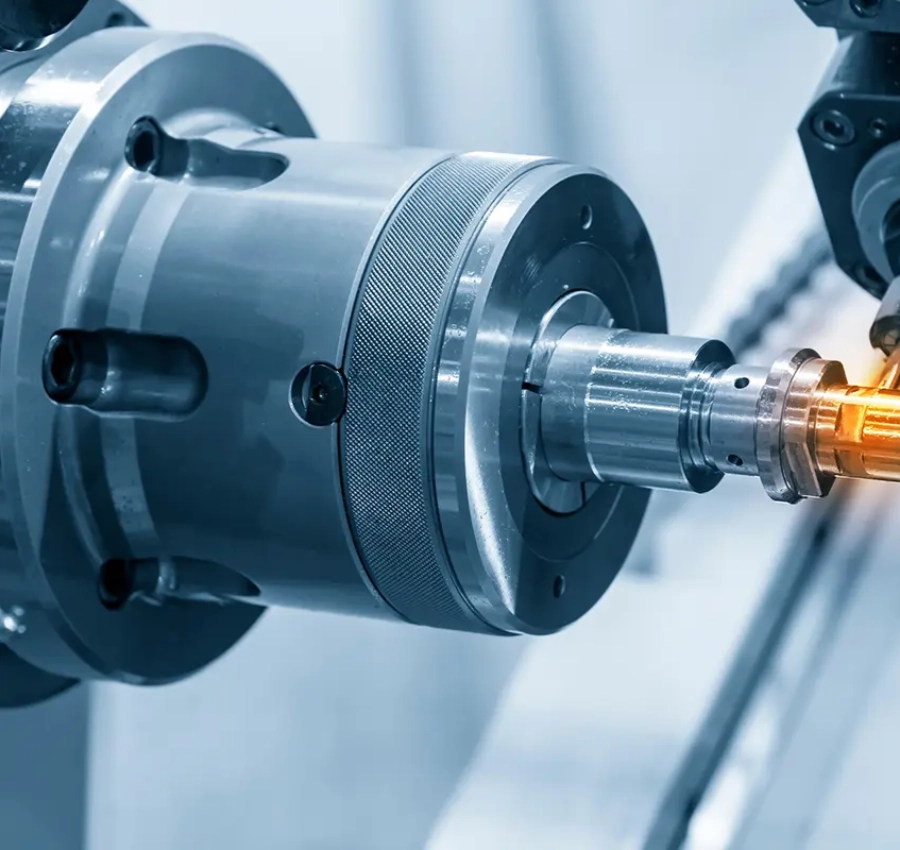

YSF Medical firmly believes that OEM encompasses more than merely converting design drawings into physical components. Over the past 30 years, we have partnered with numerous international medical device brands, gaining extensive hands-on experience with trauma implants and developing a deep understanding of the market pressures, cost challenges, and regulatory scrutiny involved in bringing a product to market. When clients present us with their design plans, we not only ensure precision manufacturing quality but also offer design-for-manufacturability recommendations. This helps refine structural details and improve production efficiency, thereby reducing risks during mass production. This approach positions us as more than just a supplier; we serve as a strategic partner from the early stages of R&D, supporting clients in addressing market challenges and clinical demands.

Quality Commitment: Ensuring Every Component Is Truly Trustworthy

Trauma implants ultimately enter the human body, leaving no room for compromise in any detail. YSF Medical has fully implemented the ISO 13485 medical device quality management system and established rigorous traceability processes to ensure that every step, from raw materials and prototyping to mass production, complies with regulatory and clinical standards. We are also highly skilled in handling medical-grade titanium alloys, stainless steel, and composite materials, providing the most suitable manufacturing solutions to meet diverse needs. To us, every plate or screw is not merely a cold piece of metal but a vital bridge connecting patient recovery and physician trust. This sense of responsibility drives us to continuously refine our processes and management. We sincerely invite you to explore our technical capabilities and join us in advancing trauma medical devices from design to clinical application.

.webp) Contact Us

Contact Us

.webp) CONTACT US

CONTACT US