In the competitive field of orthopedic implant manufacturing, efficiency, precision, and regulatory compliance are key factors for success. Traditional multi-supplier production models often lead to delays, increased costs, and inconsistent quality. A one-stop-shop solution streamlines the entire orthopedic implant production process, ensuring cost-effective, high-quality, and timely delivery.

At YSF Medical, we specialize in OEM and ODM manufacturing of orthopedic implants, providing end-to-end services from design and engineering to high-precision CNC machining, quality assurance, and supply chain management.

Table of Contents

Integrated Design & Engineering for Optimized Manufacturing

Efficient implant production starts with a well-engineered design. Our team at YSF Medical collaborates with clients to create innovative, production-ready solutions:

-

Processing Stimulation – The use of simulations to optimize manufacturing processes before actual production, helping to identify potential issues and improve efficiency

-

Rapid prototyping – Using CNC precision machining technology to quickly produce prototypes for testing design and functionality.

-

In-house Tooling(Mold/Fixture/Guage) – The process of designing and manufacturing molds, fixtures, and gauges internally, which allows for greater control, precision, and cost-efficiency during production.

By integrating engineering expertise with advanced manufacturing, we help orthopedic companies reduce time-to-market and improve implant performance.

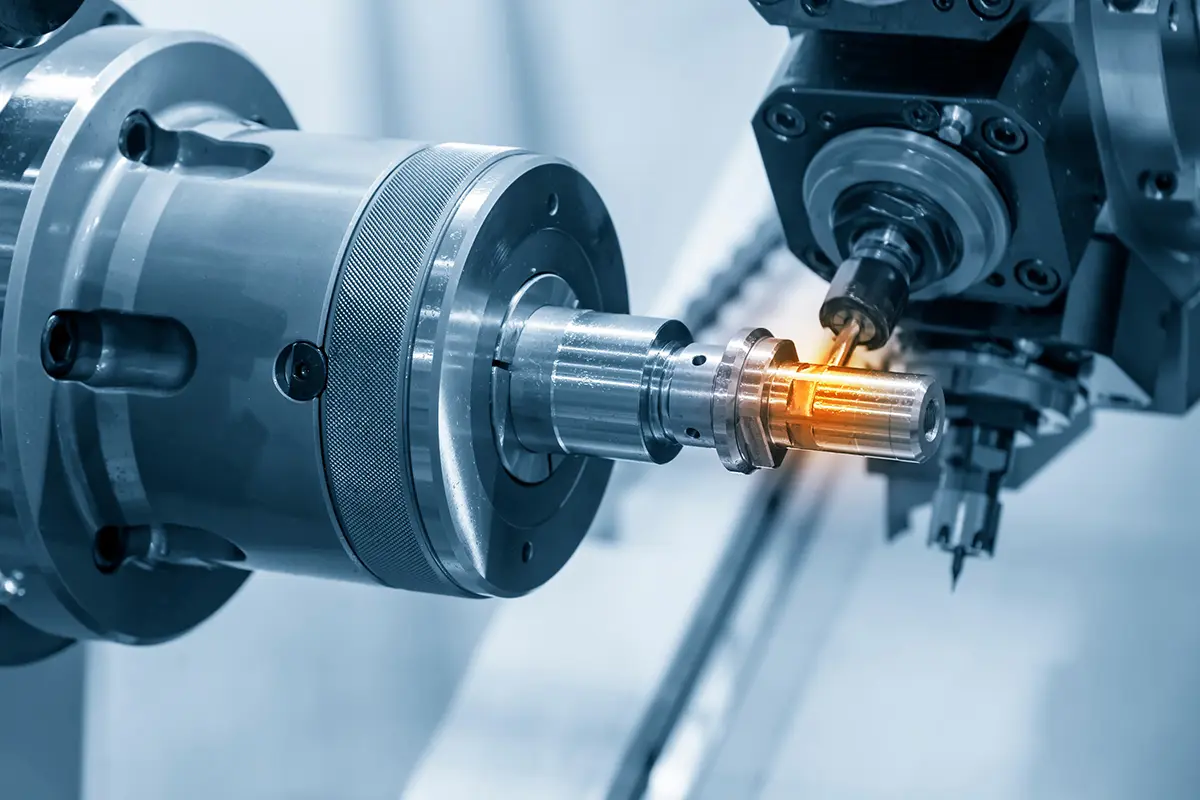

Advanced CNC Machining for Orthopedic Implants

High-precision machining is essential for orthopedic implants to meet stringent medical standards. YSF Medical employs:

-

CNC Lathe & CNC Milling – Multi-axis machining ensures complex geometries with superior accuracy.

-

Automated Production – Reducing human error and improving consistency.

-

Titanium, Stainless Steel & PEEK Machining – Supporting various biocompatible implant materials.

-

Small-batch production: Meets the medical industry's demand for low-volume, diverse products, and assists clients in process validation.

Our cutting-edge machining technology guarantees superior implant performance while maintaining cost efficiency.

Comprehensive Material & Surface Treatment Solutions

The choice of materials and surface treatments significantly impacts the longevity and biocompatibility of orthopedic implants. YSF Medical offers:

-

Medical-grade titanium & Stainless Steel – Meeting industry standards for strength and durability.

-

PEEK & Other Advanced Polymers – Lightweight, high-strength materials for specialized applications.

-

Titanium Anodizing, Sandblasting & Polishing – Enhancing implant wear resistance and osseointegration.

With our expertise in material science and surface treatment, we ensure implants meet both clinical and regulatory expectations.

ISO 13485-Certified Quality Control & Regulatory Compliance

Orthopedic implant manufacturers must adhere to strict quality and regulatory standards. YSF Medical ensures:

ISO 13485-Certified Production Process – Guaranteeing consistent compliance with global medical device regulations.

-

Comprehensive Quality Control and full traceability.–

-

Incoming Quality Control(IQC)

-

In Process Quality Control(IPQC)

-

Process Quality Control(PQC)

-

Final Quality Control(FQC)

-

Regulatory Documentation Support – Helping clients meet compliance requirements in their target markets.

With 30 years of manufacturing expertise, YSF Medical is committed to producing high-quality, regulation-compliant implants.

Streamlined Supply Chain for Cost-Effective Production

A well-optimized supply chain reduces costs and ensures timely delivery. Our one-stop orthopedic manufacturing solution includes:

-

Raw Material Sourcing & Inventory Management – Reducing procurement delays and costs.

-

End-to-End Production Control – Eliminating inefficiencies associated with multi-vendor production.

-

Logistics & On-Time Delivery – Ensuring implants reach clients on schedule.

By offering a fully integrated supply chain, we help orthopedic companies minimize risks and maximize efficiency.

Dedicated Customer Support & Long-Term Partnerships

Successful orthopedic implant production requires strong partnerships and reliable support. YSF Medical provides:

-

Technical Consultation & Engineering Assistance – Helping clients optimize implant designs and manufacturing processes.

-

Transparent Communication & Project Management – Ensuring smooth collaboration from development to delivery.

-

Scalable Manufacturing Solutions – Supporting clients as their production demands grow.

Our commitment to customer satisfaction and long-term partnerships make us a preferred choice for orthopedic implant manufacturers.

Partnering with YSF Medical enhances efficiency, reduces costs, and accelerates time-to-market in the competitive orthopedic implant industry. By eliminating the complexities of multi-vendor coordination, we ensure a seamless production process from concept to delivery. With decades of experience, ISO 13485-certified processes, and a commitment to innovation and customer collaboration, we empower orthopedic implant companies to scale efficiently, maintain product excellence, and achieve long-term market success. Choosing us means securing a reliable, cost-effective solution that drives sustained growth and competitive advantage in the global medical device industry.

Contact us today and let’s create the best orthopedic implant solutions for you! Fill out the contact form or email us at sales@ysfbone.com, and our team will respond within 24 hours!

.webp) Contact Us

Contact Us

.webp) CONTACT US

CONTACT US